- Download Catalog

Share:

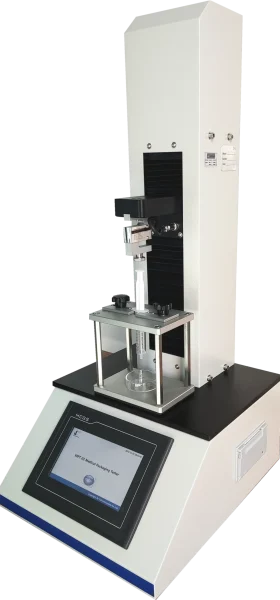

Needle Bond Strength Tester

Introduction

In the highly regulated fields of medical device manufacturing and pharmaceutical packaging, ensuring the mechanical integrity of components like hypodermic needles is essential. One critical test is the bond strength test, which measures the tensile force required to separate the needle tube from its hub. A precise and reliable bond strength tester is essential to verify compliance with international standards, including ISO 7864, ISO 11040-4, and ISO 11608-2.

Understanding the Bond Strength Tester

A bond strength tester is a specialized mechanical testing device used to measure the adhesive or mechanical bond between two components—in this case, the needle tube and hub of medical syringes. This test is essential to confirm the safety and performance of hypodermic needles under tensile stress, especially when inserted into patient tissue.

For syringe and pen injector manufacturers, this test is not optional—it’s a requirement outlined in standards like ISO 7864, ISO 11040-4 Annex G1, and ISO 11608-2 Annex B, which emphasize product safety and functional reliability.

Technical Features

- PLC control unit equipped and 7-inch HMI touch screen

- Precision ball screw and stepper motor used

- Variable test speed.

- Multiple fixtures customization available

- Position restrictor and overload protections

- Automatic returning function after test

- Dot matrix type microprinter

A high-quality bond strength tester should meet the following specifications:

- Load capacity: 0–500 N (or more, based on application).

- Speed control: Precise rate at 50 mm/min.

- High-resolution sensors: Accurate detection of peak force.

- Custom fixtures: Designed to fit syringe hubs and delicate needle tubes without deformation.

- Data acquisition: Real-time display and recording for quality documentation and analysis.

Needle Tube and Hub Testing in Accordance with ISO Standards

ISO 7864, the core international standard for sterile hypodermic needles, mandates specific procedures to evaluate bonding strength. According to Annex E, the purpose of the test is to ensure that the needle bonding system can withstand a defined tensile force based on the needle’s gauge.

Other complementary standards include:

- ISO 11040-4 Annex G1: Applicable to prefilled syringes and focuses on needle retention in the syringe system.

- ISO 11608-2 Annex B: Relevant for needle-based injection systems, especially pen injectors, specifying mechanical strength requirements between components.

These documents prescribe consistent test setups, conditions, and reporting formats to ensure accurate and reproducible measurements across the industry.

Bond Strength Between Needle Tube and Hub Test Method

The standard test procedure includes:

Sample Preparation: Use sterilized hypodermic needles under normal laboratory conditions.

Mounting: Position the sample vertically in the bond strength tester, aligning the hub in a fixed holder and gripping the needle tube without slippage.

Zeroing and Settings:

- Set the load cell to zero (ensuring no preload).

- Use a testing speed of 50 mm/min, per ISO 7864.

Testing:

Begin the test and monitor the force applied until the needle detaches from the hub or either component fails.

Results:

- Record the maximum tensile force (in Newtons) — this represents the bond strength.

Proper gripping is critical. If the needle tube slips or is pinched during the test, results may be inaccurate.

Why Bond Strength Testing Matters

A failed bond between needle and hub poses serious safety risks, such as needle detachment during injection or incorrect medication delivery. These issues can lead to:

- Medical liability

- Regulatory non-compliance

- Product recalls

- Harm to patients

Routine use of a bond strength tester ensures that manufacturers meet both safety expectations and international requirements. This enhances trust in the brand and ensures market access across different regions.

Applications Across Industries

While widely used in medical syringe testing, bond strength testers are also applicable to:

- Pen injectors

- Dental needles

- Veterinary devices

- Custom medical tubing assemblies

By adapting the test fixtures and parameters, manufacturers can extend this method to a variety of bonded components.

Configuration

Main machine, softgel holder, probe, microprinter, loadcell

Software, customized probe, loadcell, etc