Test af løsrivelse og glidekraft plays a significant role in assessing the frictional properties of materials and components, particularly in packaging and medical applications. The test involves determining the force needed to initiate and maintain movement of a surface or object. This type of testing is critical in ensuring that products like syringes operate smoothly and effectively, especially when testing the forces required to move a syringe plunger.

In this article, we will explore the importance of Test af løsrivelse og glidekraft, particularly in relation to syringe leak testing and the testing of forces required to operate the piston in syringes, as outlined in ISO 7886-1.

Syringe Leak Testing: Ensuring Proper Functionality

Syringe leak testing is essential to verify the integrity of a syringe’s design, ensuring that there is no leakage of air or liquid past the plunger stopper or seal. ISO 7886-1 sets the standards for syringe testing, focusing on performance aspects such as dead space, leakage, and the force required to operate the piston. These tests are crucial for syringes used in medical applications, as any leakage can compromise the quality and safety of the product.

ISO 7886-1 specifies that syringes must pass tests for air and liquid leakage and for the forces required to operate the piston. These tests are essential for confirming that the syringe will function properly under normal use conditions. By testing these critical performance factors, manufacturers can ensure the reliability and safety of their syringes.

Forces Required to Operate the Piston: The Importance of Break Loose and Glide Force Testing

Den force to operate the piston in a syringe is a critical parameter in assessing syringe functionality. The force required to move the piston is often referred to as bryde løs kraft og Glidekraft. Den bryde løs kraft is the initial force required to start moving the piston, while the Glidekraft is the force required to keep the piston moving once it has started.

Testing these forces is essential to ensure that the syringe plunger moves smoothly and consistently, without excessive resistance. If the force required to operate the piston is too high, it could make it difficult for the user to administer the contents, potentially causing discomfort or malfunction. On the other hand, insufficient resistance may lead to leakage or improper dosing.

Break Loose and Glide Force Testing Methods

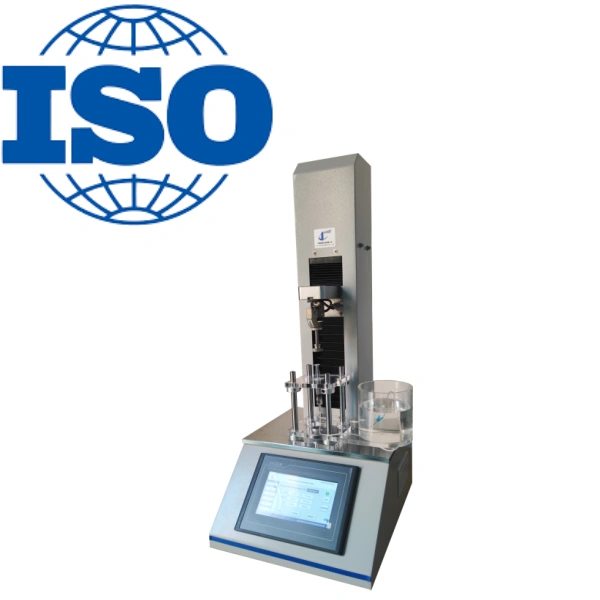

Break loose and glide force testing is typically carried out using a mekanisk testmaskine designed to measure and record the forces required to initiate and sustain piston movement. The SSR-01 Sprøjte glidemodstandstester is an example of such equipment, providing precise measurements of the forces required for smooth piston operation.

Test Procedure for Break Loose and Glide Force Testing:

- Set up the syringe: Fill the syringe with distilled water and ensure that the plunger is at the nominal capacity mark.

- Start the test: The syringe is connected to the testing machine, which moves the plunger at a controlled rate. The force required to start and maintain movement is recorded.

- Measure the force: Den bryde løs kraft is recorded when the piston first begins to move, while the Glidekraft is recorded during the sustained movement of the piston.

- Analyze results: The test results indicate whether the forces required are within acceptable limits, ensuring proper functionality of the syringe.

These results are vital for quality control, as they help manufacturers understand how their syringes will perform under real-world conditions.

Key Standards in Break Loose and Glide Force Testing

Den ISO 7886-1 standard outlines the requirements for syringe testing, including the forces needed to operate the piston. It recommends testing methods that include both bryde løs kraft og Glidekraft to ensure that the syringe performs smoothly during use. Additionally, it specifies the need for testing syringe leakage to ensure that there is no air or liquid leakage past the plunger stopper, which could affect the syringe’s functionality.

Syringe Testing for Leak Detection

Leakage testing is a critical part of syringe quality assurance. ISO 7886-1 outlines the procedures for detecting both air and liquid leakage in syringes, particularly at the plunger stopper. A syringe is considered faulty if any leakage is detected during these tests, as even small amounts of leakage can compromise the product’s effectiveness and safety.

Konklusion

Test af løsrivelse og glidekraft is essential for evaluating the performance of syringes and other materials in packaging and medical applications. By understanding and testing the forces required to operate the piston, manufacturers can ensure the quality, reliability, and safety of their products. Syringe leak testing, as defined by ISO 7886-1, provides crucial insights into the performance and integrity of syringes, helping manufacturers maintain high standards and deliver safe and effective products to the market.

For precise and reliable testing of these forces, the Cell Instruments SSR-01 Sprøjte glidende modstandstester offers an excellent solution for manufacturers and quality control personnel, ensuring that their products meet the required performance criteria.