ISO 7864 Hypodermic Needle Sharpness Testing

Introduction

Needle sharpness testing is essential for evaluating hypodermic needles, ensuring they meet safety and performance standards during medical use. Guided by ISO 7864, this testing assesses critical needle parameters to confirm compliance and avoid unnecessary pain or tissue damage during injection. In this article, we’ll discuss how to perform a comprehensive needle sharpness testing procedure, including best practices for the penetration needle test and hypodermic needle testing to meet ISO 7864 requirements.

Understanding the Importance of Needle Sharpness Testing

Sharp needles are vital in medical applications to ensure minimal discomfort, reduced tissue damage, and effective drug delivery. Needle sharpness testing evaluates a needle’s ability to penetrate various substrates with minimal force, measuring both peak penetration and drag forces. By ensuring compliance with ISO 7864, manufacturers can deliver safe and reliable medical devices, helping maintain patient comfort and safety.

Key Elements of ISO 7864 for Needle Sharpness Testing

ISO 7864 sets out the requirements and test methods for hypodermic needles for single use, focusing on precise needle performance. Specifically, Annex D of ISO 7864 outlines the penetration needle test methodology, which measures both peak penetration force and drag force during insertion into a controlled substrate.

The ISO 7864 method ensures consistency and reproducibility in testing, giving manufacturers confidence in their product quality and safety.

Penetration Needle Test and Hypodermic Needle Testing

The penetration needle test is a fundamental part of hypodermic needle testing. It involves the following components and steps:

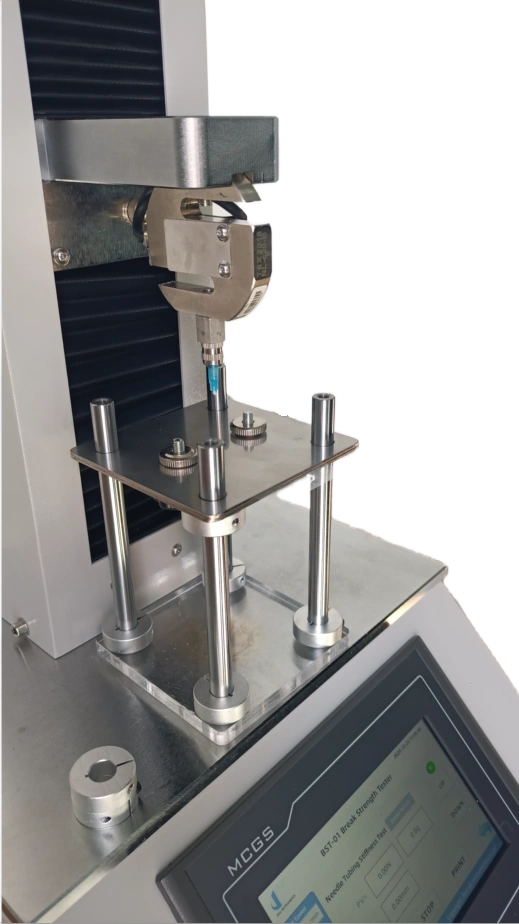

1. Force Measurement Apparatus

A force gauge equipped with a load cell records the forces acting on the needle during testing. The device also securely holds and moves the needle at a standard test speed of 100 mm/min for accurate measurement.

2. Substrate Selection

Different substrates simulate human tissue and provide a reliable test medium. Common substrates include:

- Natural latex rubber (40 ± 5 Shore A)

- Polyurethane (85 ± 10 Shore A)

- Silicone rubber (50 ± 5 Shore A)

- Polyethylene LDPE film (50 ± 5 microns)

The selected substrate must be validated to ensure consistent results.

3. Substrate Holder

A well-designed substrate holder with parallel plates securely clamps the substrate in place. The circular open penetration area (nominal diameter: 10 mm) enables precise testing and ensures accurate data collection.

4. Penetration Depth

The needle is inserted to a depth equal to 80% of its nominal length (e.g., 4 mm for a 5 mm needle). After each test, a new substrate area must be used to avoid bias.

5. Test Environment

Tests should be conducted in a controlled environment (18–28 °C; 25–75% RH) to avoid variability.

Conducting the Needle Sharpness Testing

To perform a thorough needle sharpness testing, follow these steps:

- Prepare test samples and substrate, conditioning them for at least 24 hours in standard ambient laboratory conditions.

- Mount the needle onto the force measurement device.

- Secure the substrate in the holder, ensuring alignment with the penetration target area.

- Start the penetration test by moving the needle at 100 mm/min until the desired penetration depth is reached.

- Retract the needle and record the complete force profile.

If misalignment causes the needle to collide with the substrate holder, discard the test and redo it with a properly aligned sample.

Data Collection and Analysis

The force profile generated during testing captures two main parameters:

- Peak Penetration Force: The highest force needed to pierce the substrate.

- Drag Force: The average friction force acting on the needle as it travels through the substrate.

Calculating the mean and standard deviation of these parameters ensures accurate reporting. ISO 7864 recommends using statistically significant sample sizes to validate the test data.

Reporting Needle Sharpness Testing Results

A complete needle sharpness testing report should include:

✅ Mean and standard deviation of peak penetration force

✅ Mean and standard deviation of drag force

✅ Description of the test environment and substrates used

✅ Confirmation of compliance with ISO 7864

Such comprehensive reporting ensures transparency and reliability in your testing process.

Why Choose Cell Instruments for Needle Sharpness Testing?

At Cell Instruments, we specialize in manufacturing and supplying advanced materials testing instruments, including equipment for needle sharpness testing. Our reliable testing solutions help manufacturers meet ISO 7864 requirements and ensure product safety and patient comfort. We also provide customized testing and automation solutions to fit your unique needs, supporting industries such as medical, pharmaceutical, and quality control.

Needle sharpness testing is an indispensable step in ensuring medical needles meet international safety and performance standards. By following ISO 7864’s clear guidelines and utilizing precise testing equipment, manufacturers can ensure their hypodermic needles meet the highest quality and reliability standards. Contact Cell Instruments today to learn how we can support your testing needs!

FAQs about Needle Sharpness Testing

Q1: What is the purpose of needle sharpness testing?

A1: It assesses the insertion and drag forces of a needle to ensure minimal pain and tissue damage, improving patient comfort.

Q2: Which standards regulate needle sharpness testing?

A2: ISO 7864 outlines the required procedures and performance criteria for hypodermic needle testing.

Q3: What substrates are used for testing?

A3: Common substrates include natural latex rubber, polyurethane, silicone rubber, and LDPE films.

Q4: How is the drag force calculated in needle sharpness testing?

A4: It’s determined by calculating the average friction force from 80% of the penetration depth region on the force profile.

Q5: Can Cell Instruments provide custom needle sharpness testing solutions?

A5: Yes, we offer tailored testing equipment and automation solutions to meet your specific product testing needs.