In the quality assurance of medical syringes, glide force testing plays a pivotal role in assessing the smoothness and reliability of piston movement. It directly impacts user safety, comfort, and product compliance with critical international standards. This article explores the essentials of glide force testing, including related parameters like break loose force, and how standards such as ISO 11040-4, ISO 7886-1, and ISO 8537 guide the testing process. We will also introduce the Cell Instruments MST-01 Syringe Functionality Tester, a reliable solution for laboratories and manufacturers performing syringe functionality testing.

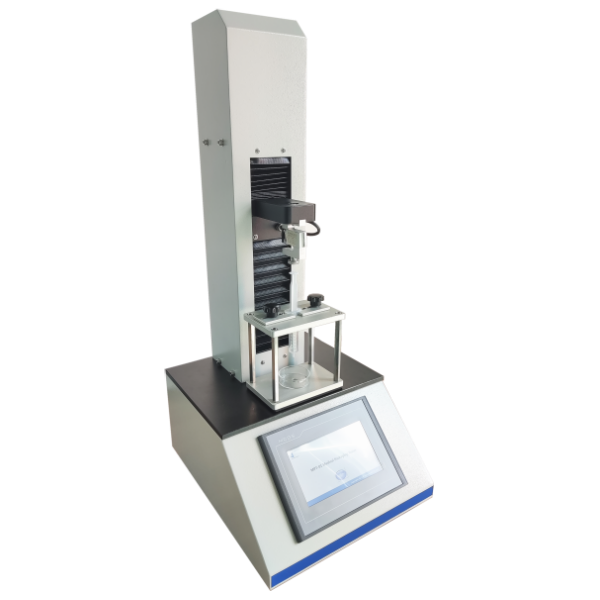

MST-01 Glide Force Tester by Cell Instruments

To ensure precise syringe functionality testing, we recommend the Cell Instruments MST-01 Glide Force Tester. This instrument supports testing per:

- ISO 11040-4

- ISO 7886-1

- ISO 8537

Features:

- Full-automatic measurement of glide force and break loose force

- Programmable test speed (100 mm/min ± 5%)

- Compatible with various syringe sizes

- High-precision force sensors (up to 0.01 N resolution)

By using MST-01, manufacturers can streamline compliance testing, improve quality control, and maintain consistent syringe performance.

What Is Glide Force and It Matters

Glide force refers to the resistance a plunger encounters as it moves along the barrel of a syringe. It is a key indicator of syringe usability and performance. If the force is too high, it can cause pain or dosing errors; if too low, it may indicate defective sealing or leakage risk. Glide force is usually measured in Newtons (N) and is evaluated at three key stages:

- Break loose force (Fs): The initial force required to start plunger movement.

- Mean force (F): The average resistance during sustained plunger motion.

- Maximum force (Fmax): The highest resistance encountered during travel.

These parameters must fall within specific ranges defined by ISO 7886-1, ISO 11040-4, and ISO 8537 to ensure compliance.

Glide Force Test Methods per ISO Standards

ISO 7886-1 Annex E: Glide and Break Loose Force Test

ISO 7886-1 defines test methods for single-use manual syringes. The method uses a mechanical testing machine to expel water from a syringe while recording the force needed to move the piston.

Key Test Steps:

- Preparation: Fill the syringe with water (23 ± 5 °C) after pre-conditioning.

- Mounting: Connect the syringe to a reservoir and attach the plunger to a drive head.

- Testing: Move the plunger at a controlled rate (100 ± 5 mm/min) and record:

Break loose force (Fs)

Mean glide force (F)

Maximum force (Fmax)

ISO 11040-4 Annex E: Glide Force Test for Prefilled Syringes

This method applies to glass barrels and sterilized subassembled syringes ready for filling. It evaluates lubrication quality—either from silicone oil or the plunger stopper material—by measuring glide force using a universal testing machine.

Key Test Steps:

- Plunger Insertion: Set the plunger stopper using vent tube or vacuum stoppering.

- Stopper Positioning: Test at 50% or full nominal fill volume to assess glide behavior.

- Rod Installation: Attach plunger rod, threaded or unthreaded.

- Mounting: Place the syringe in an adaptor plate on the testing machine.

- Testing: Move the plunger at 100 mm/min until it contacts the barrel shoulder.

- Recording: Capture the maximum force between break loose and the sharp rise near stroke end.

ISO 8537 Annex C: Glide Force Test for Insulin Syringes

This method measures operating forces in insulin syringes to ensure consistent dose delivery and smooth piston movement.

Key Test Steps:

- Preparation: Fit syringe with needle and fill to 50% nominal capacity.

- Mounting: Fix syringe vertically, needle pointing downward.

- Testing: Apply downward force to the plunger and record:

Break loose force (Fs)

Mean glide force (F)

Maximum force (Fmax)

Best Practices for Syringe Glide Force Testing

To achieve accurate, repeatable results, follow these guidelines:

- Ensure proper alignment of syringe and test fixture.

- Control test temperature to within 23 ± 5 °C to avoid material expansion or viscosity issues.

- Eliminate air bubbles in the reservoir system, even if standards say it won’t affect the test.

- Record data digitally for traceability and audit purposes.

Common Challenges in Syringe Glide Force Testing

- Non-uniform barrel surfaces may increase friction.

- Plunger deformation can result in inconsistent readings.

- Misaligned test fixtures may affect force measurement.

- Inappropriate test speeds can lead to unreliable results.

Regular calibration and SOP adherence are essential to overcome these challenges.

Glide force testing is a critical component of syringe functionality testing. It verifies whether syringes meet international performance criteria for smooth plunger motion, which directly impacts user safety and product compliance. By following protocols outlined in ISO 7886-1, ISO 11040-4, and ISO 8537, and using professional testing equipment like the MST-01 from Cell Instruments, quality assurance professionals can ensure consistent and accurate test results.