ISO 7864

Hypodermic Syringe Functionality Testing

When it comes to sterile hypodermic needles, patient safety and product performance are non-negotiable. That’s where ISO 7864 plays a vital role. This international standard outlines comprehensive requirements and test methods to evaluate hypodermic needles for single-use syringes, including syringe functionality testing, needle penetration test method, and strength of needle bond. Manufacturers, quality control engineers, and regulatory bodies rely on ISO 7864 to ensure consistent product quality and safety.

What Is ISO 7864 and Why It Matters

ISO 7864 is the International Standard for sterile hypodermic needles intended for single-use with syringes or infusion equipment. It defines the needle’s physical requirements, dimensions, performance characteristics, packaging, and test methods for evaluating:

- Penetrability

- Bonding strength

- Needle tube integrity

- Corrosion resistance

- Syringe compatibility

Compliance with ISO 7864 ensures that needles perform reliably under clinical conditions, reducing risks for both patients and healthcare providers.

ISO Syringe Functionality Testing

Syringe functionality testing ensures the needle is compatible with its designated syringe and performs effectively during injection. Parameters tested include:

- Compatibility with Luer connectors

- Plunger force

- Injection force consistency

- Dead space minimization

These evaluations are critical for an ISO syringe to pass certification. Cell Instruments provides solutions that assess functionality by measuring insertion force, plunger resistance, and force distribution during injection.

Needle Penetrability Test

One of the most important test under ISO 7864 is the needle penetration test method, also known as the penetrability test.

Test Principle

A needle is inserted into a standardized substrate at a constant speed (typically 100 mm/min). The peak penetration force and drag force are recorded to evaluate ease of penetration and consistent movement.

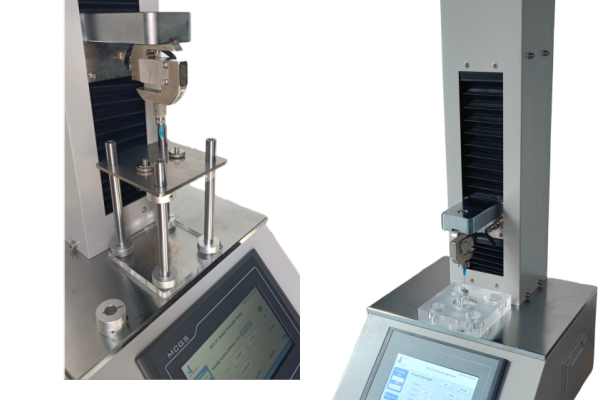

Key Equipment

- Force measurement system with precision load cell

- Needle holder with axial alignment

- Validated substrate (e.g., latex rubber or LDPE)

- Penetration depth gauge (typically 80% of needle length)

Cell Instruments offers automated needle penetration tester with programmable speeds and digital force analysis to ensure accuracy and repeatability in compliance with ISO 7864 Annex D.

Drag Force and Peak Penetration Force

Two main results are derived:

- Peak Penetration Force: Max force required to pierce the substrate

- Drag Force: Average force needed to maintain penetration over 80% of needle length

These metrics reflect needle sharpness, friction, and manufacturing consistency. For regulatory submissions and design validation, precise measurement is crucial.

Strength of Needle Bond Test

Bond strength refers to the adhesion between the needle tube and the hub—a weak bond could lead to detachment during injection, posing a serious hazard.

Testing Procedure (ISO 7864 Annex E):

- Needle is gripped vertically on a universal testing machine

- A tensile force is applied at 50 mm/min

- The maximum force at which detachment or failure occurs is recorded

Cell Instruments provides universal tensile tester with customized fixtures for needle bonding test, ensuring compliance with Annex E procedures.

Cell Instruments Compliance with ISO 7864

Cell Instruments specializes in precision testing solutions for medical device manufacturers, offering:

- Needle Penetrability Tester

- Universal Bond Strength Tester

- Syringe Functionality Testing Systems

- Customized fixtures for Luer lock compatibility and needle holding

- Automation upgrades for repeatability and throughput

All instruments are built to align with ISO 7864, ISO 8537, ISO 7886, and USP 381 standards. Our systems support statistical analysis, data export, and traceable calibration certificates.

FAQs

ISO 7864 specifies requirements and test methods for sterile hypodermic needles for single use. It covers physical dimensions, materials, and performance test.

It evaluates the interaction between syringe and needle, including injection force, sealing, and ease of use to ensure consistent and safe operation.

A needle is inserted into a standardized material at 100 mm/min. Peak and drag forces are recorded to evaluate sharpness and performance.

The tensile force needed to detach the needle from the hub. It verifies mechanical integrity under applied stress.

Cell Instruments’ automated penetrability tester and universal tensile tester are ideal for ISO 7864-compliant needle and syringe evaluation.