ISO 9626

Test rurki igłowej ze stali nierdzewnej

ISO 9626 określa wymagania i metody testowania rurek igłowych ze stali nierdzewnej stosowane w produkcji urządzeń medycznych, takich jak igły podskórne i kaniule. Ta międzynarodowa norma gwarantuje, że rurki używane w zastosowaniach medycznych spełniają spójne wymagania dotyczące wydajności i bezpieczeństwa. Dwa kluczowe testy zgodne z normą ISO 9626 to test sztywności rurki i odporność rurki na test pęknięciaktóre są niezbędne do oceny integralności mechanicznej i trwałości rur ze stali nierdzewnej.

Co to jest ISO 9626?

Norma ISO 9626, pełny tytuł "Rurki igłowe ze stali nierdzewnej do produkcji wyrobów medycznych - Wymagania i metody badań"dotyczy sztywny przewód igły ze stali nierdzewnej nadaje się do produkcji igieł podskórnych i innych elementów urządzeń medycznych.

Norma ISO 9626 odgrywa kluczową rolę w zapewnieniu, że rurki ze stali nierdzewnej stosowane w igłach medycznych mają wystarczające właściwości. wytrzymałość mechaniczna, elastycznośćoraz odporność na zmęczenie. Rurki, które nie spełniają tych wymagań, mogą spowodować zgięcie lub złamanie igły podczas użytkowania, stwarzając zagrożenie dla pacjentów i pracowników służby zdrowia.

Standard definiuje:

- Specyfikacje materiałowe dla rur ze stali nierdzewnej.

- Tolerancje wymiarowe w tym grubość i średnica ścianki.

- Testy właściwości mechanicznychtakie jak sztywność i odporność na pękanie.

Przestrzeganie normy ISO 9626 pomaga producentom utrzymać stałą jakość produktów i zachować zgodność z międzynarodowymi przepisami dotyczącymi urządzeń medycznych.

Podczas oceny rurek do urządzeń medycznych szczególnie istotne są dwa aspekty wydajności mechanicznej:

Test sztywności rurki

The test sztywności rurki ocenia odporność rurek igłowych ze stali nierdzewnej na odkształcenia po przyłożeniu siły. Zgodnie z normą ISO 9626, załącznik B, test obejmuje podparcie określonej długości rurki na obu końcach i przyłożenie znanej siły. siła skierowana w dół w jego centrum. Kwota odchylenie jest następnie mierzona w celu określenia sztywności.

Ten test zapewnia wgląd w to, jak bardzo rurka będzie się zginać pod obciążeniem - kluczowy czynnik zapewniający, że stabilność igły podczas wkłuwania.

Przegląd procedury

-

Rurka jest umieszczona na aparat do badania sztywności z określoną rozpiętością opartą na jego rozmiarze.

-

A tłok ładujący przykłada siłę skierowaną w dół z prędkością pomiędzy 1 mm/min i 10 mm/min.

-

The odchylenie w punkcie załadunku jest rejestrowana z dokładnością do 0,01 mm.

Wyższa sztywność wskazuje na mocniejszą rurkę, która jest odporna na zginanie, podczas gdy niższa sztywność może sugerować zwiększoną elastyczność. Obie właściwości są ważne w zależności od zamierzonego zastosowania medycznego.

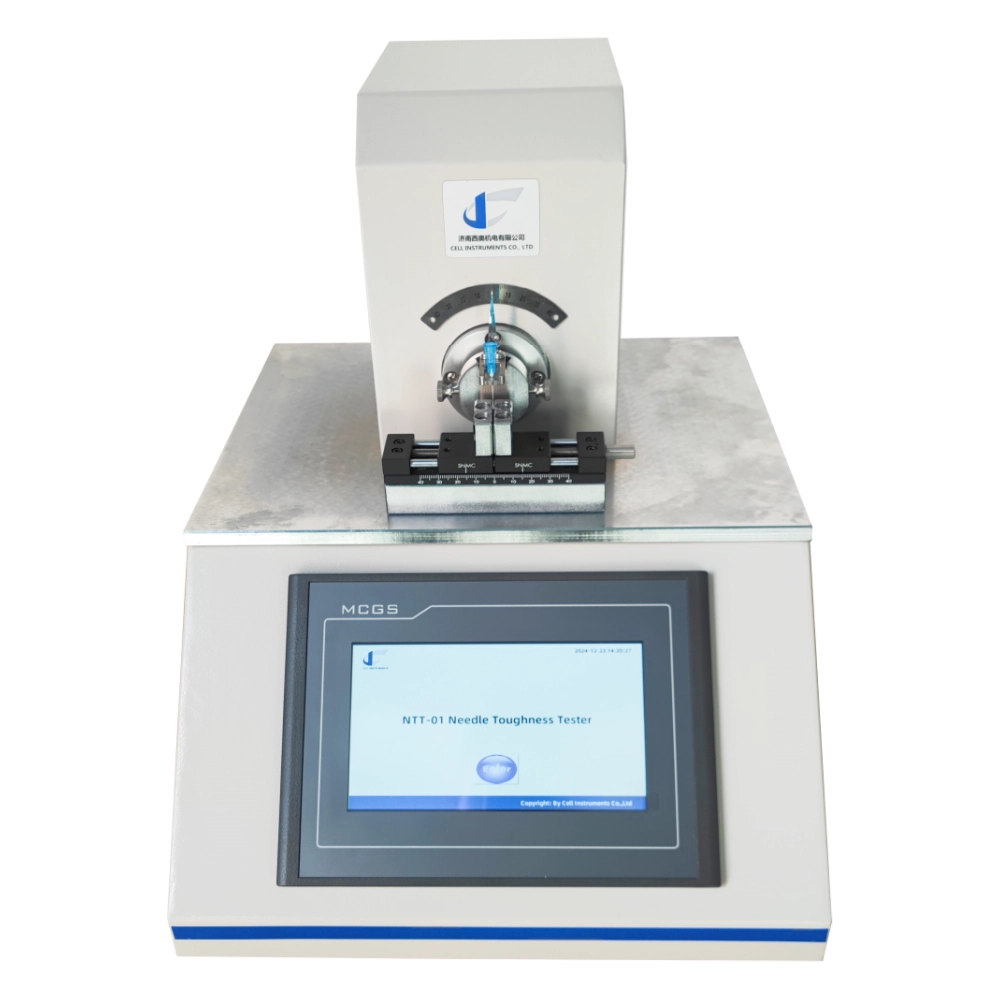

Tester sztywności Cell Instruments oferuje precyzyjnie kontrolowany system załadunku i cyfrowy pomiar przemieszczenia, w pełni zgodny z wymaganiami ISO 9626. Umożliwia laboratoriom wykonywanie Testy sztywności rurek igłowych ze stali nierdzewnej z wysoką dokładnością i powtarzalnością.

Odporność rurki na pęknięcie

The odporność rurki na test pęknięcia (ISO 9626 Załącznik C) ocenia zdolność rurki do wytrzymania wielokrotnego zginania bez pękania lub łamania. Symuluje to rzeczywiste warunki, w których igła może być poddawana cyklicznym naprężeniom podczas obsługi lub użytkowania.

Zasada testu

Jeden koniec rurki jest sztywno zamocowany, a drugi powtarzająca się siła zginająca jest przykładana w określonej odległości. Rurka jest zginana naprzemiennie w przeciwnych kierunkach pod określonym kątem - zazwyczaj 25° dla rur o regularnych ściankach, 20° dla cienkościennychoraz 15° dla rurek o bardzo cienkich ściankach - dla 20 pełnych cykli.

Po zakończeniu testów przewody są sprawdzane wizualnie pod kątem jakichkolwiek oznak pęknięcia.

Cell Instruments Tester odporności na zerwanie Posiada programowalną cykliczną kontrolę ruchu i precyzyjny system przemieszczania kątowego, umożliwiający dokładną ocenę rurki. odporność na zmęczenie oraz trwałość.

Najczęściej zadawane pytania

A: ISO 9626 to międzynarodowa norma określająca wymagania i metody testowania dla Rurki igielitowe ze stali nierdzewnej stosowany w produkcji urządzeń medycznych. Określa parametry dotyczące wymiarów, sztywności, odporności na pękanie i ogólnej wydajności mechanicznej.

A: The test sztywności rurki zapewnia, że rurka zachowuje wystarczającą sztywność i nie wygina się nadmiernie pod obciążeniem. Ma to zasadnicze znaczenie dla stabilności i precyzji igieł medycznych podczas ich wprowadzania.

A: Ten test mierzy zdolność rurki do wytrzymania powtarzające się cykle gięcia bez pękania. Pomaga to potwierdzić trwałość i bezpieczeństwo rurek medycznych ze stali nierdzewnej w zastosowaniach klinicznych.

A: Tester sztywności i odporności na pękanie firmy Cell Instruments są specjalnie zaprojektowane do wykonywania testów zgodnych z normą ISO 9626, oferując precyzyjną kontrolę siły, zautomatyzowany pomiar i niezawodną powtarzalność.

A: Inżynierowie kontroli jakości, technicy laboratoryjni i producenci urządzeń medycznych, którzy produkują lub walidują Rurki igielitowe ze stali nierdzewnej powinien przeprowadzić te testy, aby zapewnić zgodność z międzynarodowymi normami bezpieczeństwa.